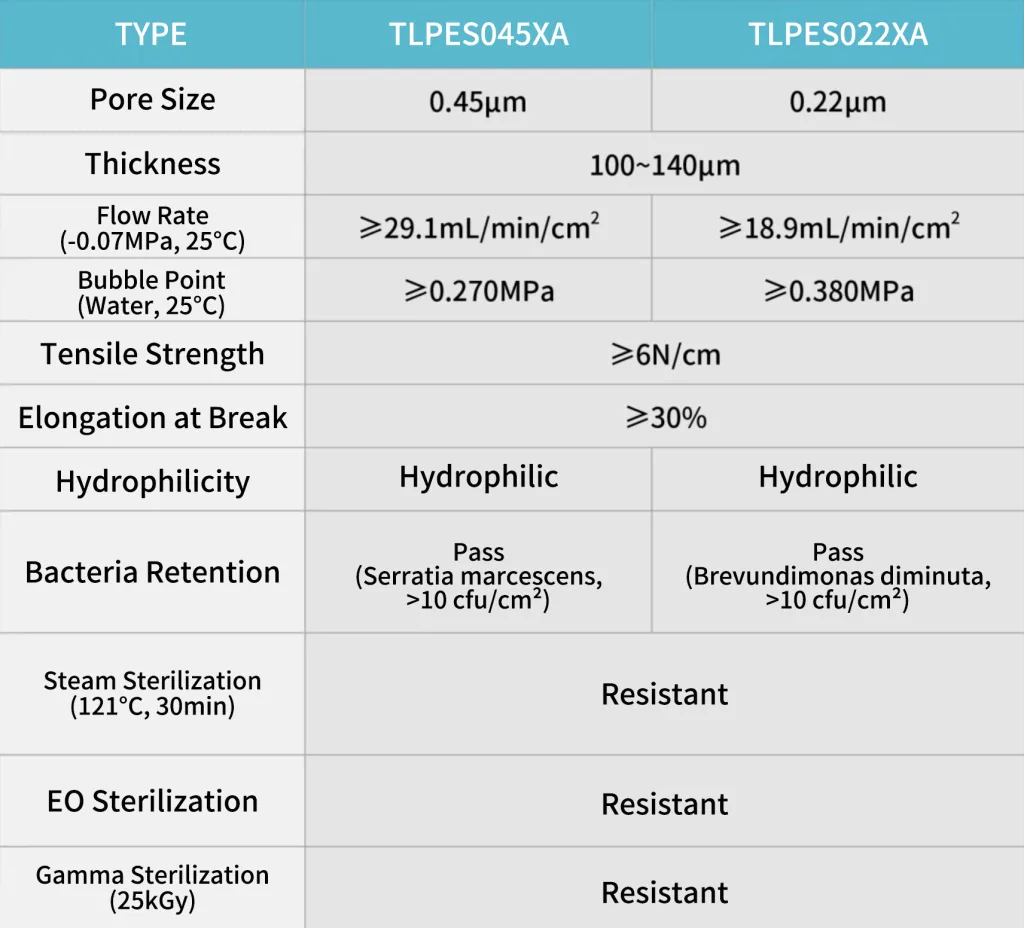

Polyethersulfone (PES) is a high-performance polymer material with a high glass transition temperature (225℃). Microporous PES filtration membranes made of PES exhibit excellent heat resistance, mechanical strength, and hemocompatibility, making them widely used in the electronics industry, food & beverage, healthcare, and other fields.

Different industries have distinct requirements for the pore structure of PES membranes.

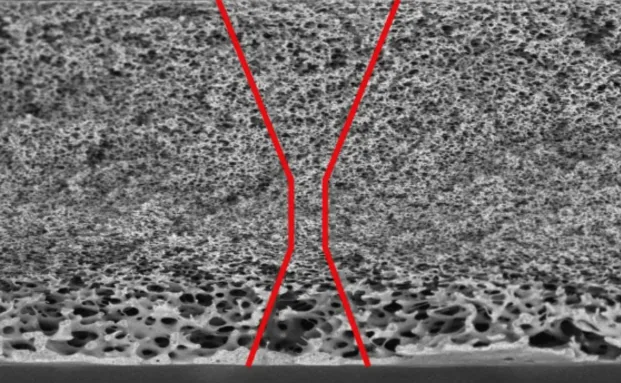

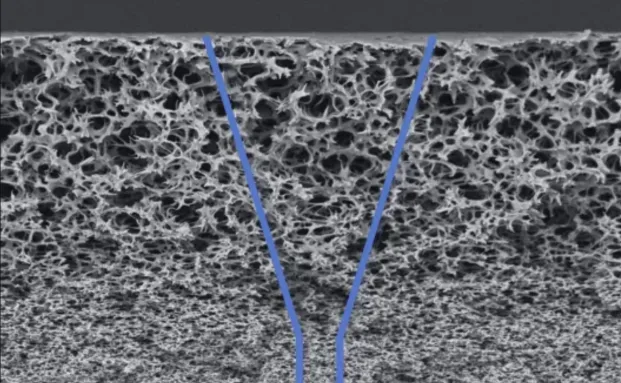

These membranes are categorized into symmetric and asymmetric structures. Asymmetric membranes are further classified based on their pore size gradients: standard asymmetric (approx. 1:10 ratio), highly asymmetric (1:10 to 1:100+), and the specialized “hourglass” asymmetric structure.

For instance, the electronics and F&B sectors prioritize high dirt-holding capacity, favoring highly asymmetric membranes. In contrast, the pharmaceutical industry demands a critical balance between process safety and high throughput, making the “hourglass” asymmetric structure the ideal solution.

After years of R&D, the team at Tailin has successfully developed the XA Series PES Membrane with an “hourglass-shaped” asymmetric structure, following the launch of the “V-shaped” highly asymmetric PES membrane.

The XA Series utilizes an hourglass pore design to maximize integrity and safety during processing and filtration. By optimizing the balance between selectivity and flux, the XA Series is specifically engineered for the rigorous demands of biopharmaceutical and chemical pharmaceutical manufacturing.

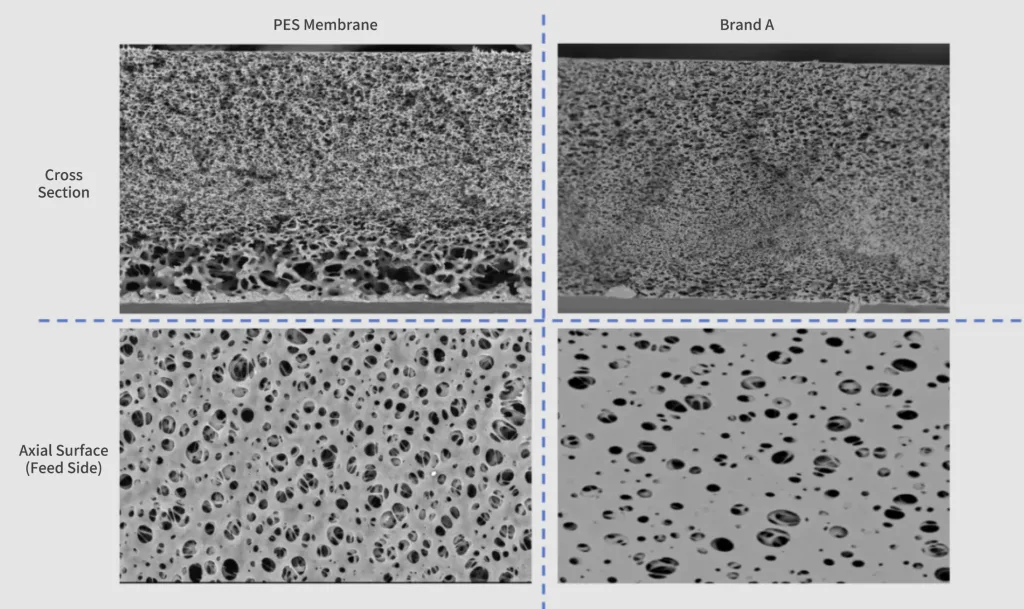

SEM Microstructure Comparison

SEM characterization results show that the XA Series PES Membrane features higher cross-sectional porosity and a superior surface opening rate (surface porosity) compared with Brand A.

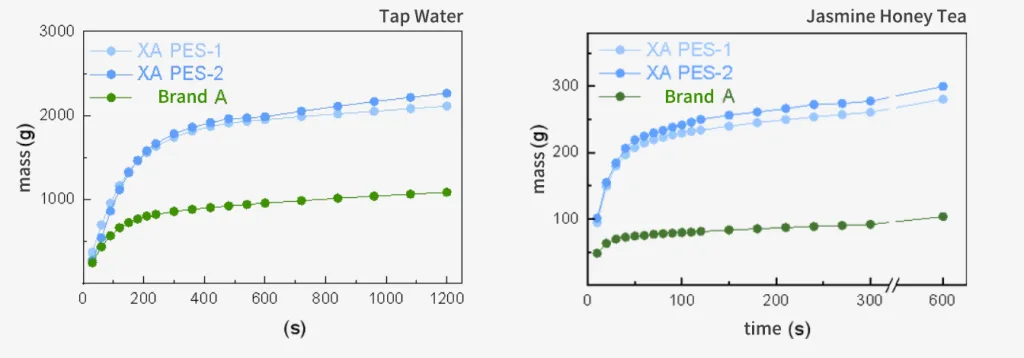

Under a constant pressure of 0.1MPa, the filterability of the XA Series PES Membrane and Brand A (same pore size specification) was tested with tap water (same batch) and jasmine honey tea.

The results demonstrate that, thanks to its unique pore geometry, the XA Series PES membrane delivers a significantly higher total throughput compared to Brand A.

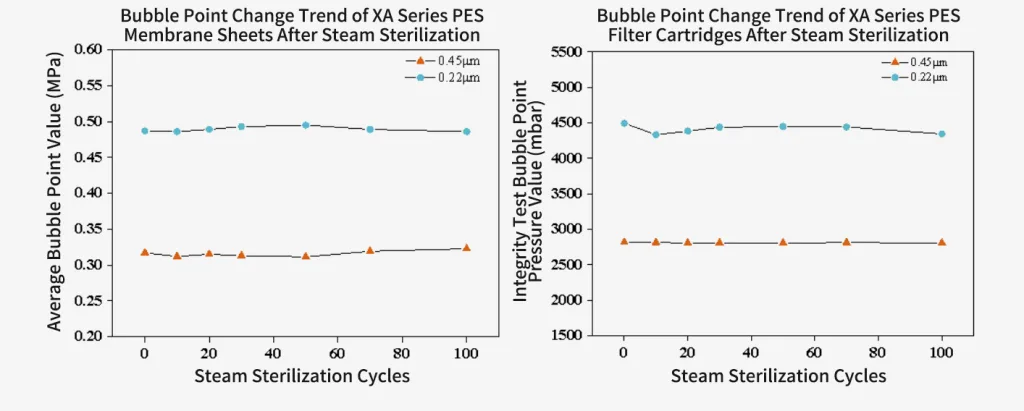

Resistance to steam sterilization was evaluated for both the membrane discs and the assembled pleated cartridges under offline conditions at 121°C for 30 minutes per cycle.

Test data shows that after 100 sterilization cycles, both the membrane and cartridge bubble points remained stable without significant deviation. This confirms that the XA Series PES membrane exhibits excellent durability and thermal stability during repeated steam sterilization.

The XA Series PES membrane delivers exceptional all-around performance, ensuring both process safety and high filtration efficiency. It provides biopharmaceutical and chemical pharmaceutical manufacturers with a more versatile and reliable filtration membrane solution for their critical filtration needs.

For more information or to explore partnership opportunities, please visit our website or contact us at phone: +86 571 8658 9087, email: marketing@tailingood.com. Stay connected with Tailin through our social media channels on Facebook, YouTube, and Instagram to witness our ongoing journey toward excellence and innovation.

Read Our One More Blog: Filtailin® MCE 0.45μm Membrane: Empowering Bio-pharmaceutical R&D and Production