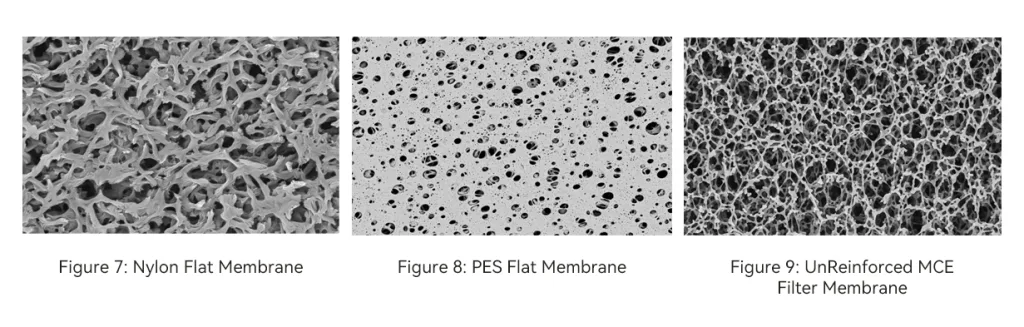

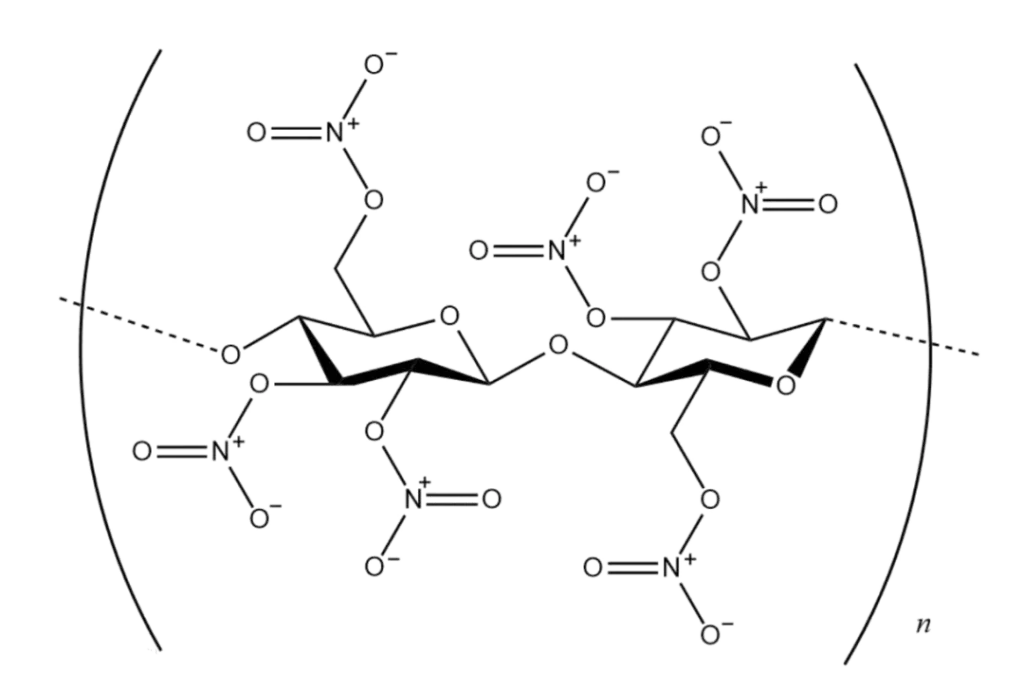

Mixed Cellulose Ester (MCE) microporous membranes represent the earliest commercially produced variety of microporous membranes, with a history spanning over a century. The primary raw materials for manufacturing MCE membranes are Cellulose Nitrate (CN) and Cellulose Acetate (CA), which are derived from cellulose—a natural polymer—via nitration and acetylation respectively, making them highly eco-friendly.

Figure 1: Chemical Structural Formula of Cellulose Nitrate

Figure 2: Chemical Structural Formula of Cellulose Acetate

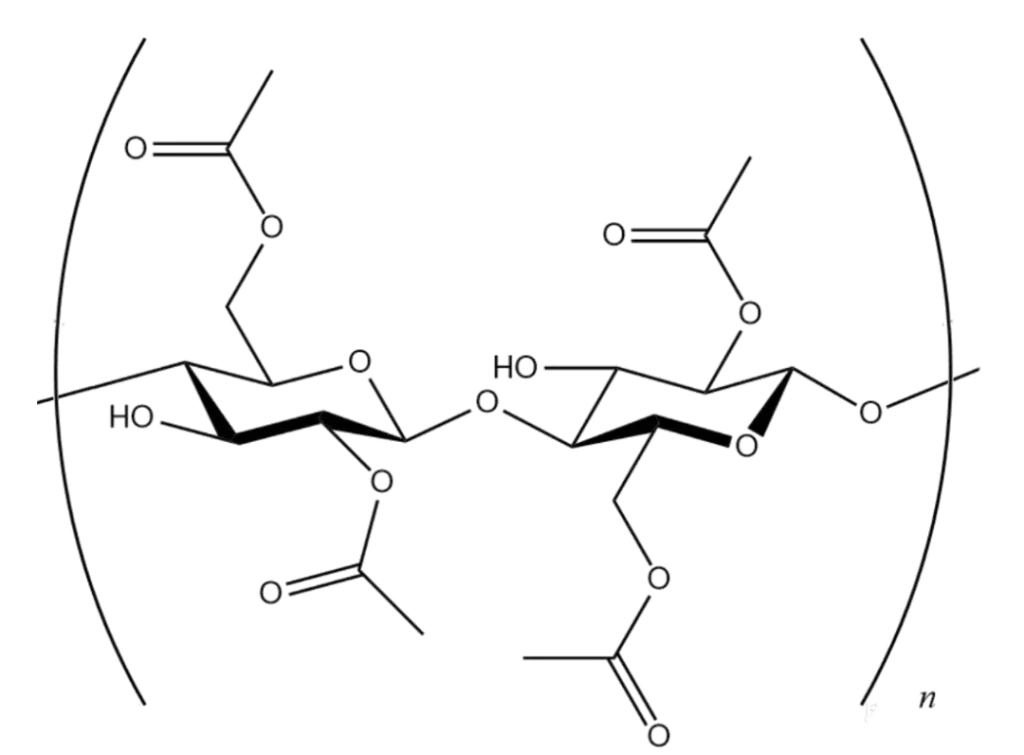

Filtailin® MCE 0.45μm Membrane is fabricated by uniformly casting cellulose polymer on both sides of a polyester non-woven fabric substrate. It boasts excellent mechanical strength, high retention efficiency and zero fiber shedding risk, making it ideal for filtration and separation processes in the biopharmaceutical industry.

Figure 3: Filtailin® MCE 0.45μm roll film finished Membrane and SEM Micrographs

01 Typical Applications

It is mainly applicable to the critical pre-filtration step for reducing bioburden and particle load in sterilization and virus removal filtration processes, so as to protect more expensive downstream filtration devices from premature clogging.

02 Product Advantages

Ⅰ Processability

Designed specifically for the manufacture of pleated filter cartridges. Benefiting from the reinforcement effect of the polyester non-woven fabric substrate, Filtailin® MCE 0.45μm membrane overcomes the drawbacks of unsupported MCE filter membranes that cannot be pleated and are difficult to weld.

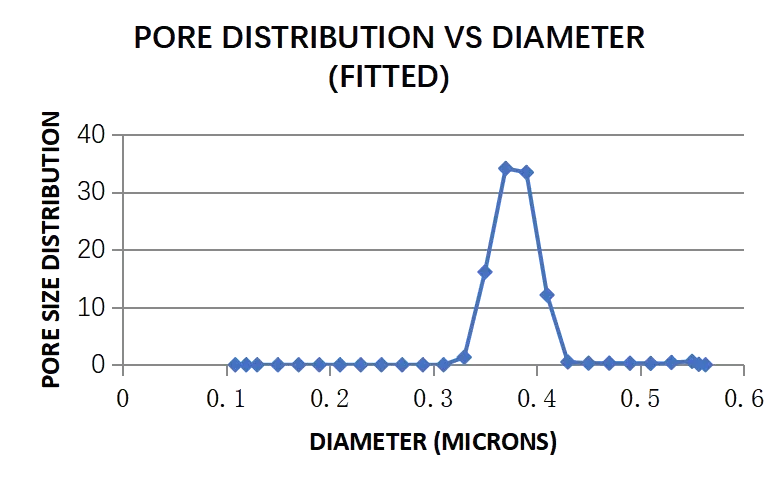

Ⅱ Pore Size Distribution

Tested by the PMI pore size analyzer, Filtailin® MCE 0.45μm membrane features a concentrated pore size distribution around 0.4μm, with no macropore defects.

Figure 4: Pore Size Distribution of Filtailin® MCE 0.45μm Membrane

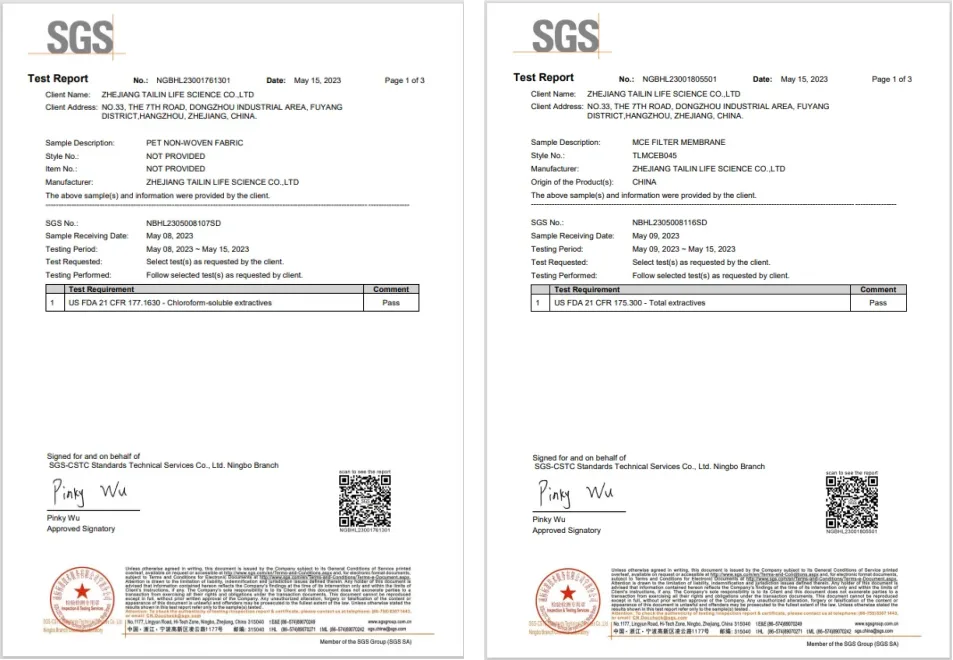

Ⅲ Indirect Food Additives

All component materials of the Tailin Filtailin® MCE 0.45μm membrane meet the FDA requirements for indirect food additives under 21 CFR 175-177.

Figure 5: Test Report of Filtailin® MCE Membrane

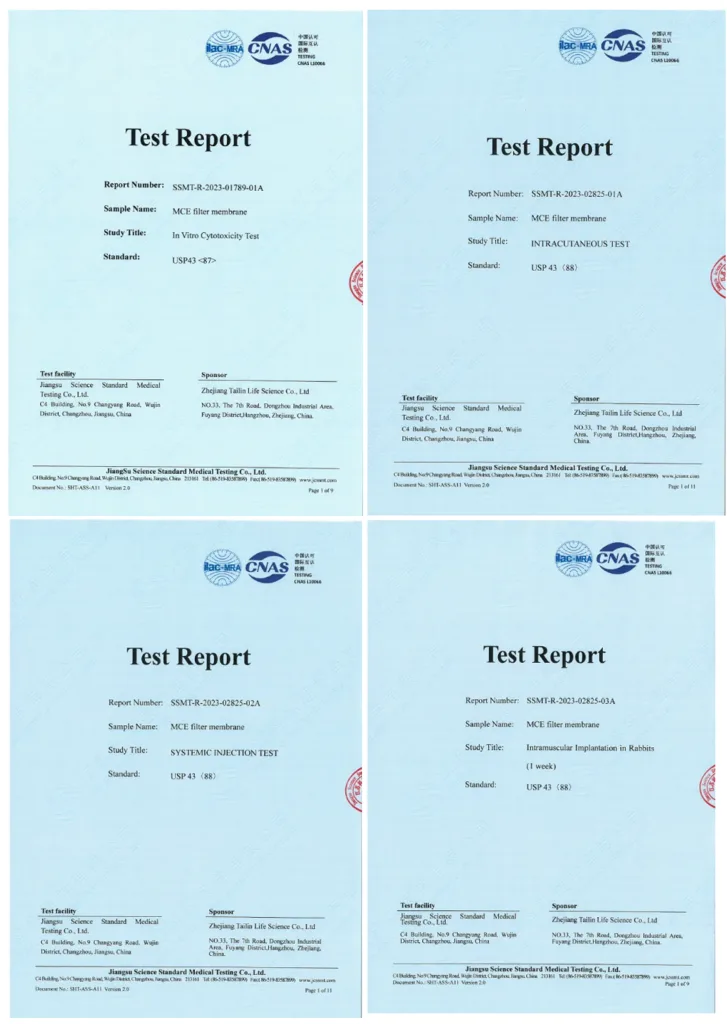

Ⅳ Biosafety

Filtailin® MCE 0.45μm Membrane complies with the plastic requirements specified in USP 43 <87> and USP 43 <88> Class VI.

Figure 6: Test Report of Filtailin® MCE 0.45μm Filter Membrane

Ⅴ Low Extractables

In accordance with GB/T 34244-2017 standards, after extraction in purified water at 25°C ± 2°C for 24h ± 2h, the extractable content of the Tailin Filtailin® MCE 0.45μm membrane is measured at ≤50 mg/m².

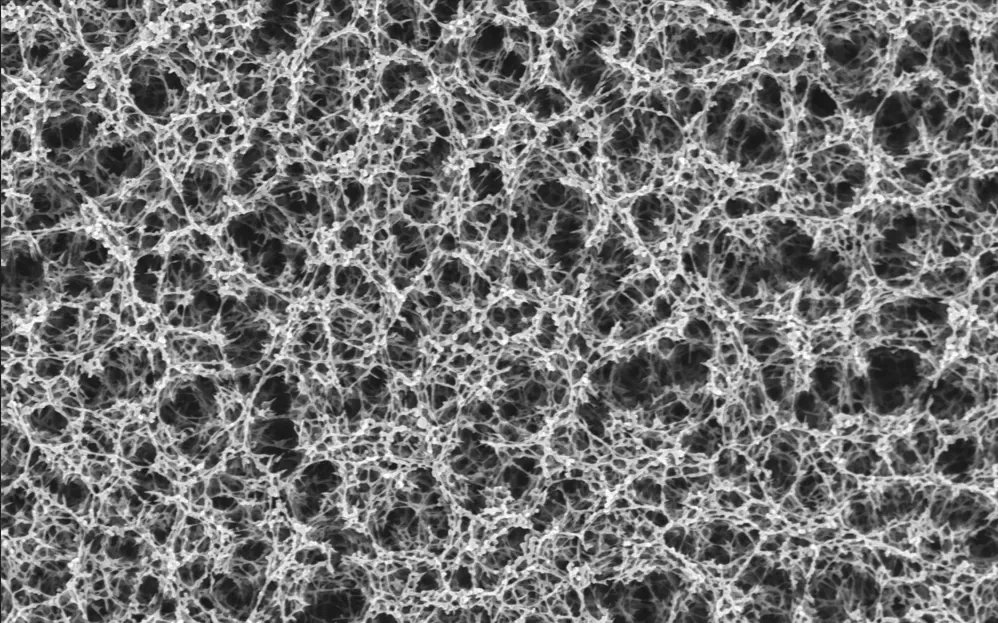

03 More Products